FunderMax has completed over 10,000 projects in India. Please tell us about some of the iconic buildings that stand out for their unique façade, and which have stood the test of time.

The first impression is always important, and it is no different when it comes to buildings. The façade makes an important contribution in making a lasting impression of the building. ITES company’s global R&D centre in Bangalore is an example of one such iconic corporate office building façade execution, which was completed in 2016. A mix of seven shades with different sizes was used to form a pixelated effect on the building façade. It was designed by Architect Rajiv Hanumanthaiah, Design Director at Lateral Architectural.

For the development of Navodaya Educational Trust Raichur in Karnataka, a world-class building with cutting-edge double skin façade design, we designed a unique façade system that ensured thermal comfort and glare control along with low thermal transmission (U-Value) and low solar heat gain coefficient (G-Value) value. The acoustic performance of the building was improved, and less noise was transmitted to the interiors of the building. This was one-of-a-kind project because the design of the building ensured thermal, visual and acoustic comfort to the students and was also aesthetically appealing. It was designed by Architect Gayathri Shetty from Gayathri and Namith Architects (GNA), and completed in 2013.

“Cladding applications are going to be an integral part of every building in times to come, not only for aesthetics, but also for sustainability of the building”

In the design of Sattva Galleria, Bangalore, the most important part of the design was the west side. It was a huge vertical space of 3000 sqm that needed to be cladded with an appropriate façade material that could gel well with the glass panels and the cement walls. Identifying the exact façade material was extremely critical to the project. Of the many options (ACP, mosaic etc.) explored by Ar. Sudhakar Pai (of Sudhakar Pai Associates in Bangalore), FunderMax emerged as the final choice.

Project: Classic Arena, Location: Hosuru ,Bangalore, Client: Classic Constructions, Architect: PN Architects, Products: Max Compact Exterior F-Quality, Surfaces: NT, Decor: 0794 Patina Bronze, Substructure: Aluminium, Assembly type: Riveted

FunderMax guaranteed color fastness and firmness (non-peeling) of the panels. Its unique ventilated system allowed free flow of air between the façade and the wall, thus providing insulation from heat and cold. The architect interspersed the façade with colored, glossy and matte finish panels for an exciting look. While the glossy ones created a subtle shimmer, the matte version gave a high/low visual contrast. As the design metaphor was a sailing ship, white color was chosen for the façade, giving it a stylish and up-market feel. Apart from the aesthetic advantages, white colored panels absorb less heat and do not degrade over time. The project was completed in 2017.

24 Karat in Jogeshwari, Mumbai, is our oldest project (15 years old). The multiplex is designed by renowned architect Nitin Killawala, and is a very good testimonial of sustainable performance.

How has the approach to a façade’s concept and design evolved over the years in Indian architecture?

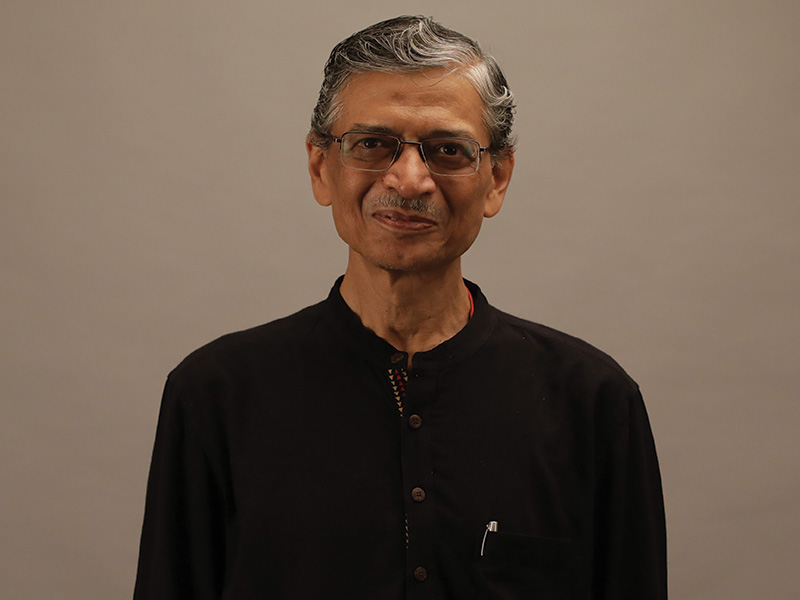

FunderMax entered the Indian market with the very clear vision of being a trendsetter in design and aesthetics for the cladding industry through high quality innovative products and solutions. Our endeavour is to bring world-class premium cladding material to the Indian market. The initial response was encouraging as well as challenging. During the initial days, we focused on creating awareness about the product concept and architectural usage in the Indian market. The challenges were creating awareness about the product and its applications, educating the market on the right fixing arrangements, getting projects to work upon, finding and training skilled technicians for application, and keeping in mind the price sensitivity.

The exterior grade high pressure laminate industry was still at a nascent stage. We worked closely with our esteemed customers to understand their project requirements and offer right solutions as per international standards. The product began to gain acceptability in the market as we began creating elegant but small projects across India. In time, FunderMax evolved from a product supplier to a complete solutions provider with the launch of its own profiles and accessories for application of FunderMax panels, which today, are being serviced through a network of 48 business partners across 38 cities.

We are the number one company in the High-Pressure Laminate industry in India and are helping architects and their customers create iconic projects in all segments. We want to be the trendsetter in design and aesthetics, and be seen as a great brand to associate with for sustainable and energy-efficient facades.

Project:Sattva Galleria, City:Bangalore, Architect: Sudhakar Pai Associates/SPA, Client: Salarpuria Sattva Group, Products: Max Compact Exterior | F-Quality, Surfaces: NT, Gloss Decor: 0085 White, Sub-structure: Aluminium, Assembly Type: Riveted

What trends do you see emerging?

There’s no doubt that sustainability has become the buzzword for any building’s façade system. Looking at the this trend, FunderMax provides the rainscreen façade system that improves building protection by enhancing the functionality of the façade with respect to heat and noise reduction, and better weather protection.

We can increase thermal efficiency of the building with an effective design. A well-designed façade reduces the thermal bridges, condensation of water vapour, protects the building and increases sustainability. We contribute to an elegant, vibrant façade as per the architect’s intent by providing technical support in the form of designs, drawings, and optimization, to facilitate faster decision making to customers/architects/façade consultants.

What innovations are impacting façade design, material and construction?

With the emergence of new materials and new technologies, and people’s constant pursuit of different building appearances, the market for façade fabrication has become bigger in size. A vast variety of new materials, such as high-pressure laminates (HPL), UHPC (Ultra High Performing Concrete), Carbon Fiber, Metals, ETFE Membranes and Solid Surfaces are available due to the technical advances in recent years.

Adherence to the strictest energy and quality parameters has given rise to more energy-efficient, innovative, and adaptable façade cladding materials and systems. Yet, a thorough assessment of the sustainability of new materials should be done to ensure that the materials used do not compromise the performance requirements of the building.

Project: Navodaya Educational Trust, Location: Raichur, Karnataka, Architect: Gayathri & Namith Architects, Décor: MAX EXTERIOR 0161 Light Afro, QTY: 1100SQM

Which façade material would you recommend in the Indian context, and why?

The Indian cladding industry is in a growing stage in terms of the materials and technology and there is a growing acceptability with regards to premium quality products in façade application. The cladding applications are going to be a necessity and would be an integral part of every building in times to come - not only for aesthetics, but also for sustainability of the building.

Technological innovations have given rise to more robust, energy-efficient, innovative and adaptable façade systems such as back-ventilated, double-skin, louvers and energy-efficient façade cladding systems. These advancements have led to innovative cladding materials such as exterior grade HPL compact laminates (as per EN438), glass fibre-reinforced concrete (GFRC), metal cladding (zinc, copper, aluminium and steel), polycarbonate panels, fibreglass-reinforced plastics, clay tiles, etc. Of the materials available, compact laminate offers high flexibility and design freedom with multiple options in finishes and decor. Moreover, the panels can be customised via CNC cutting into any motifs the architect wants to create.