The reclassification of Formaldehyde by the International Agency for research on Cancer as CARCINOGENIC TO HUMANS has triggered enormous concern globally. Lack of awareness in India on the formaldehyde emissions from UF bonded panels is even more worrisome.

The furniture is a functionally needed utility value keeping in view the ergonomic design for good working conditions. Good lighting and aesthetics enhance the interiors. One of the most neglected aspects in India is the awareness to keep the level of formaldehyde emissions released from the furniture to acceptable level in the office or home interiors, more particularly the formaldehyde emissions from the wood panels used in the fabrication of furniture like Plywood, Blockboard, Particleboard, and Medium Density Fibreboards (MDF).

Why is Formaldehyde emission so critical and important?

Formaldehyde exposure potentially causes a variety of symptoms and adverse health effects, such as eye, nose, throat, and skin irritation, coughing, wheezing, and allergic reactions. Long-term exposure to high levels of formaldehyde has been associated with cancer in humans. Formaldehyde can affect people differently. Some people are very sensitive to formaldehyde at a certain level while others may not have any noticeable reaction to the same level.

What affects formaldehyde levels in indoor air?

Formaldehyde levels in indoor air can vary depending on temperature, humidity, and air exchange rate within the indoor space. In addition, several studies have shown that in the presence of ozone, formaldehyde levels increase; therefore, the outdoor and indoor ozone levels are also relevant. Formaldehyde levels in internal office or home spaces may change with the season, day-to-day, and day-to-night. Levels may be high on a hot and humid day and low on a cool, dry day.

What are the major sources of indoor formaldehyde emissions in our offices or homes today?

Measuring formaldehyde emissions from individual consumer products is difficult because a variety of products in the office or homes can release formaldehyde or trap formaldehyde emitted from other sources. Products with greater emissions and larger surface areas in the office or homes will most likely have a greater contribution to indoor air formaldehyde levels. Keep this in mind when prioritizing the following different product types.

Pressed-wood and wood-based products: Pressed-wood (i.e., hardwood plywood, particleboard, and medium-density fiberboard (MDF)) and wood-based products, especially those containing UF resins, may be a significant formaldehyde source.

Wallpaper and paints:

- Moderate levels of formaldehyde initially following application.

- Some paints are now found with low-VOC formulations.

Re-emitters: Because they are porous, products, such as carpets or gypsum board, do not contain significant amounts of formaldehyde when new. However, they may trap formaldehyde that is emitted into the air from other products and later release it into the indoor air.

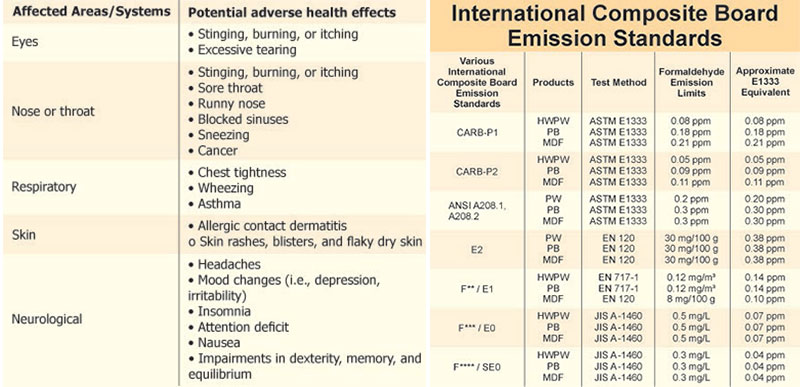

What are some of the symptoms and potential adverse health effects of formaldehyde exposure?

Formaldehyde exposure can cause a variety of symptoms and potential adverse health effects. A person's ability to smell a chemical odor, such as formaldehyde, does not always mean that the levels of the chemical are of concern or will cause an adverse health effect. Therefore, some people can smell formaldehyde before being adversely affected by it.

You can reduce exposure to high levels of formaldehyde by:

- Installing wood floors or finishes that are not "acid-cured", which is a type of finish that is formaldehyde-based.

- Installing pressed-wood products, such as particleboard, MDF, or hardwood plywood, for construction of all office furniture and interiors stamped in compliance to E1 emission norm at the most minimum. There are panel products even lower than E1 like E0, or CARB P2 and F**** available in market.

Definitions:Standards

CARB-P1:- California Air Resources Board Phase 1 emission standard (Allow sell-through date for PB & MDF is unitil Dec 31, 2011)

CARB-P2: - California Air Resources Board Phase 2 emission standard (Enforcement date for PB & MDF is Jan 01, 2012)

ANSI A208.1 & 2: - North America voluntary standards ANSI A208.1-2009 Particleboard & ANSI A208.2-2009 MDF (include most of industrial particle boards and MDF)

E2: - European E2 emission standard (Most import products from Asia are E2 or worse)

E1: - European E1 emission standard

E0: - European E0 emission standard

SE0: - European Super E0 emission standard

F**: - Japanese F-Star2 emission standard

F***: - Japanese F-Star3 emission standard

F****: - Japanese F-Star4 emission standard

JIS: - Japanese Industrial Standard

Products

HWPW: - Hardwood / Plywood

PW: - Industrial plywood

PB: - Particleboard

MDF: - Medium density fiberboard

Units

ppm: - Parts per million

Attention and concern is required from all office and home furniture manufacturers to purchase the wood panels at least having the minimum E1 certification for the safety and health concern of the people working in the office environment for which they supply the furniture made in their factories. Buyers also must make conscientious decisions while ordering furniture.