The Stylish Tiles

Flooring tiles are making an impression at the first step inside. We take a look at the growing popularity of the vitreous flooring tiles market.

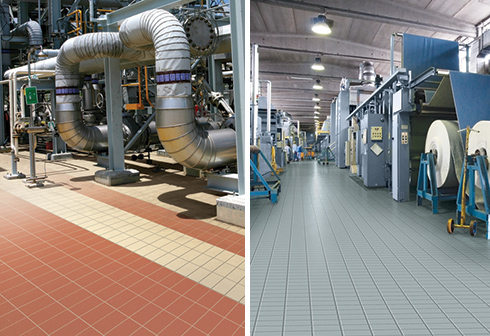

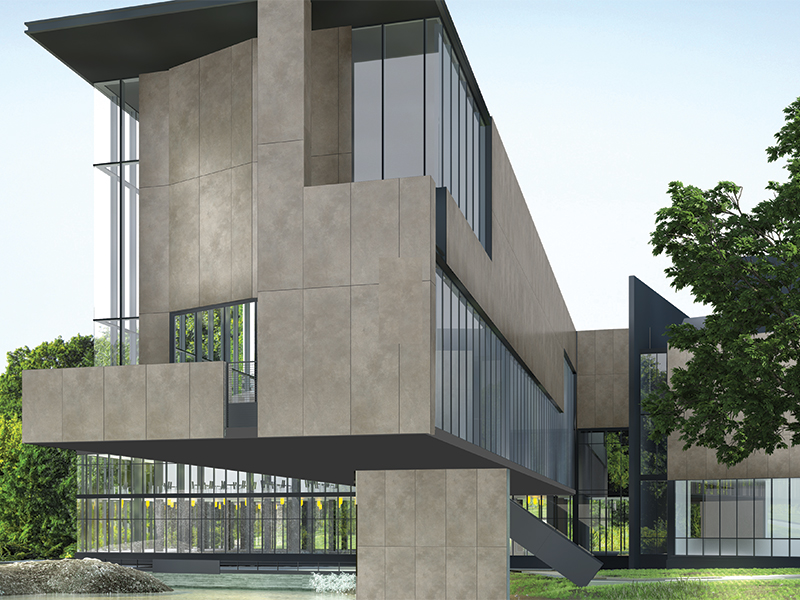

"When you dance, your purpose is not to get to a certain place on the floor. It's to enjoy each step along the way." Wayne Dyer Make an aesthetic impression, be durable, easy affordable maintenance and be fast to install – these are the most commonly laid down conditions for most architectural and interior elements for any given projects. Achieving client satisfaction, while looking for a chance to free their creativity, these professionals are always updating on products in the market that would work both ways. Before the details of the interior design are worked out, it is the choice of flooring that sets the mood, the psychological nature of the area to be covered. The other areas to canvas are the walls and the ceiling. And within the flooring options, the versatile vitreous flooring tiles, a ceramic based product are emerging especially as a sure fit. It is an emerging solution to meet aspirations of aesthetics and longevity with adequate availability on demand.

Expanding floor coverings

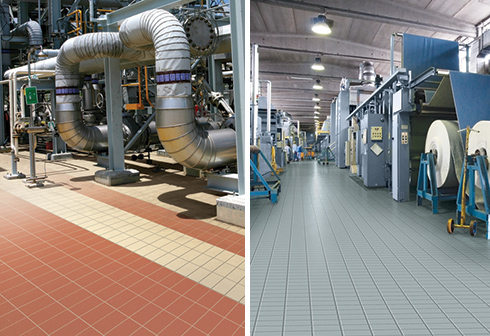

The main purpose of floor tiles is protection. However, with technological advancements vitrified tile products offer plenty of design options like digital prints, stain free or surface finishes including marble, stone, rustic, metallic, satin or matt finishes. There are some tiles that absorb heat and keeping interiors cool. Tiles are also cut in a variety of styles that are in consistent with contemporary design. Elaborates

Mr. Rajesh Kumar, Head-Hindware Tile division "High definition multi-color digital printing technology offers perfect replacement of natural marble and wooden flooring which technically superior and reduce the consumption of prestigious natural resources. Full body vitrified tiles in matt finish are perfect suit for high traffic commercial areas as any polished surface loses its sheen due to heavy wear & tear in high traffic areas. This transformation and progress in the industry now gives unlimited choice for the consumer to match their flooring with the overall décor of a house and commercial places." Telling us more about the products and the demand in the market, says

Mr Sushil Mehta, GM-Marketing, Century Tiles "Of the major categories in flooring options for buildings — vitrified, ceramic and marble —the vitrified tiles category is the one that witnessed the highest demand growth in the last five years. Higher durability and easier maintenance compared to both cheaper options, such as ceramic tiles and dearer ones, such as marble, have helped this category cash in on the steady demand for construction material."

Attributes like durability and therefore value for money is a much quoted reason for this flooring choice. As they have a high modulus of rupture, they are strong enough and can easily resist stains and scratches. "Majority of people nowadays go for vitrified tiles as they have a very high water absorption capacity. They are easy to install and last up to 15-20 years at least and are also cost-effective in comparison to marble and granite" is the experience of

Mr Ravi Aravamuthan, General Manager, H&R Johnson (India). The company also offers after sales services to their customers that addresses the complaints and helps providing solutions by resolving issues through home visits.

Know your vitreous tile

There is often confusion between the terms Vitreous/Porcelain tile and Ceramic tile. Very simply, vitreous tile is a type of ceramic tile. Indoors or outdoors, the vitreous tile range fits anywhere as the options of design, texture and durability levels can be tailored for the project in hand. When the need is to make an impression of quality, just tile it!

"Vitrified tiles are non-glazed tiles. Their hardness and polish is achieved by virtue of the pressing together of very hard materials. Vitrified tiles are extremely strong and durable and processed in such a way that they allow for very little water absorption. Vitrified tiles have a water absorption rating of < 0.1%.

Vitrified tiles allow for a "full body" tile, which means that the design is not merely on the surface of the tile, but runs throughout the entire tile. The advantage of this is that the tiles become incredibly strong.

The sizes that is available for vitrified tiles 600 x 600 mm, 800 x 800 mm and 1000 x 1000mm

The technology used for making vitrified tiles includes Soluble Salt (SST), Double Charge (DCH) Full Body, Micro Powder a.k.a. Dry Application Powder and Hi-Coat Nano Technology",

Mr. Vivek Talwar, MD, Nitco Ltd.

Strong market spread

Manufacturers of vitreous tiles have a prevalent optimistic mood regarding the market growth. Explaining the phenomenon, Rajesh Kumar details "Texture, dimension, color and design will be driving innovation moving ahead and role of technology will play a crucial part. In the nearly 16,000 crore tile market in India, vitrified floor tiles have a 48% share. The view is shared by others in the vertical. "The market is doing very well, Indian Tile industry is worth Rs.18,000 crore, out of which almost 50% share is with vitrified tiles. At present, we hold 22% share in the organized sector of Indian Tile industry. With the expansion of our manufacturing capacity at Dewas unit in Madhya Pradesh, we have become India's largest tile manufacturer with manufacturing capacity over 54 million sqm. We expect to generate over Rs.100-150 crore revenues annually, once the Dewas unit reaches peak production," expresses Ravi Aravamuthan.

A relation between the products and client budget is also seen. According to Sushil Mehta, "Demand has grown at a compound rate of 16% annually for vitreous tiles. The cheaper ceramic tiles have seen demand grow at only 8 percent annually in the last five years." Talking of the client profile and flooring choices,–

Mr. Ketan Sheth, Chief Designer/MD, Goldmine Project Consultant feels that "Clients going for vitreous flooring tiles depends on the economic class i.e. upper class has lower percentage about 40%, high-middle class 70% and middle class 80%."

Tiling progress

While the Indian market has always offered a variety of ceramic category products, being a largely unorganized sector, quality, design and size uniformity have been suspect. With established names setting shop, a customer can be sure of getting a standard product, in the quantity he requires. The growing design and texture collections, many of them mimicking natural finishes, are also encouraging. Buyers are now prepared to stretch budgets just that bit to indulge their fantasy of a perfect finish, for what would be a permanent fixture in their homes or at work. Speaking of their Century Tiles brand, Mr Mehta says, "We are competitive in the market. And at par with the international market as far as machinery and technology is concerned." Highlighting the effort put into bringing innovative and high quality products into the market, Ravi Aravamuthan says "We have in-house designers who work on new designs and innovations. We also take opinions from architects so that we can incorporate their ideas and make our products consumer-friendly. Our R&D Centre is located at Pen and is approved by Department of Scientific and Industrial Research, Government of India. Our products undergo regular and stringent quality tests right from the initial stage to the final development stage. Geologists regularly do on-site testing at the mines from where raw materials are procured." These initiatives support and encourage market growth through customer satisfaction.

As the domestic industry grows, new technologies are imported and some developed in house. The drive to remain competitive in the export market and match up with global players is helping improved products to be manufactured in the country. For example, according to Mr Mehta "For manufacturing vitrified tiles, advanced technology is borrowed from different countries like Italy and Ukraine. Ball clay is imported from Ukraine and this coupled with the modern technology to produce vitrified tiles in the longest kiln in India and subjected to a temperature of 1200 degree calices makes these tiles extremely strong."

Cost to company

Higher investment for retail adds to the stresses of higher costs of raw material, freight, power and gas. Prevalence of design piracy also hurts, as does the availability of cheaper products from other countries like China, Indonesia and others. The industry is addressing this with increased focus on customer relations to benefit from increased employment, higher earning and the lifestyle changes. Cladding and modern finishes are growing in demand. Organized players are connecting with strong distribution channels in various formats like retail outlets, dealers, sub-dealers and retail franchises too. They are also handling competition by taking over smaller units, especially from the unorganized sector to increase their market presence. There is general trend to increase preparedness to take on competition, both international and domestic and profit. All that and a growing range of specialized products like industrial floorings, vitreous tiles are paving their way to expanding acceptability everywhere.